No products in the basket.

29

Jul

Better Flatpack: Behind the Scenes

We like to take you behind the scenes at Grain- after all, what we do is pretty fun so why wouldn’t we want to share?! Being the busy bees that we are, we’re involved in a constant cycle of research, development tests, and improvements- all in the name of making better flatpack furniture.

I should probably mention something quite important at this point- we’re on a mission to bring sustainable flatpack furniture to the world. Woop! Nothing if not ambitious us lot.

So, when designing something that’s going to be with you for a very long time… what do we have to do? Well, it has to be easy to move house, foolproof when it comes to assembly, and engineered in such a way that it never loses integrity when put up many, many times. And it definitely shouldn’t be made of materials that represent a passing fad.

Sounds easy enough, but to get this stuff right is challenging stuff… after all that’s why you don’t see this sort of thing around much.

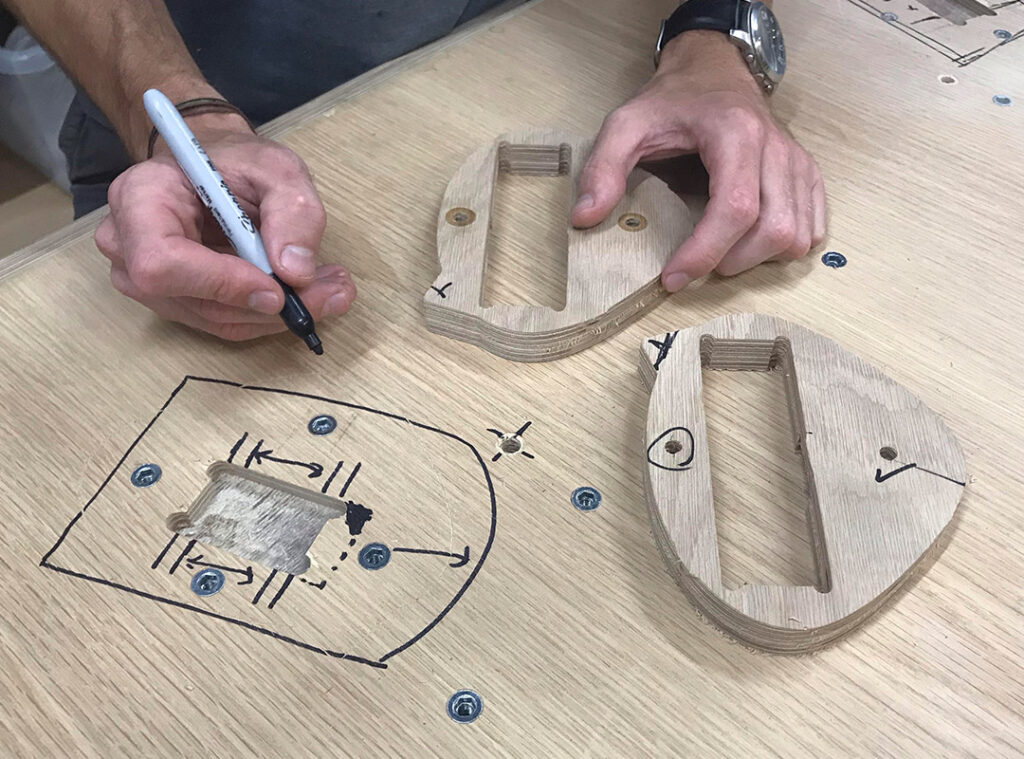

At grain, if there’s an option for lots of talking… it tends to get taken. Here myself and our lead designer Jamie are discussing design tweaks. Taking a table leg joint that’s being developed and making it as sexy as possible. It’s literally foolproof, and so strong you can jump on the table if you so wished.

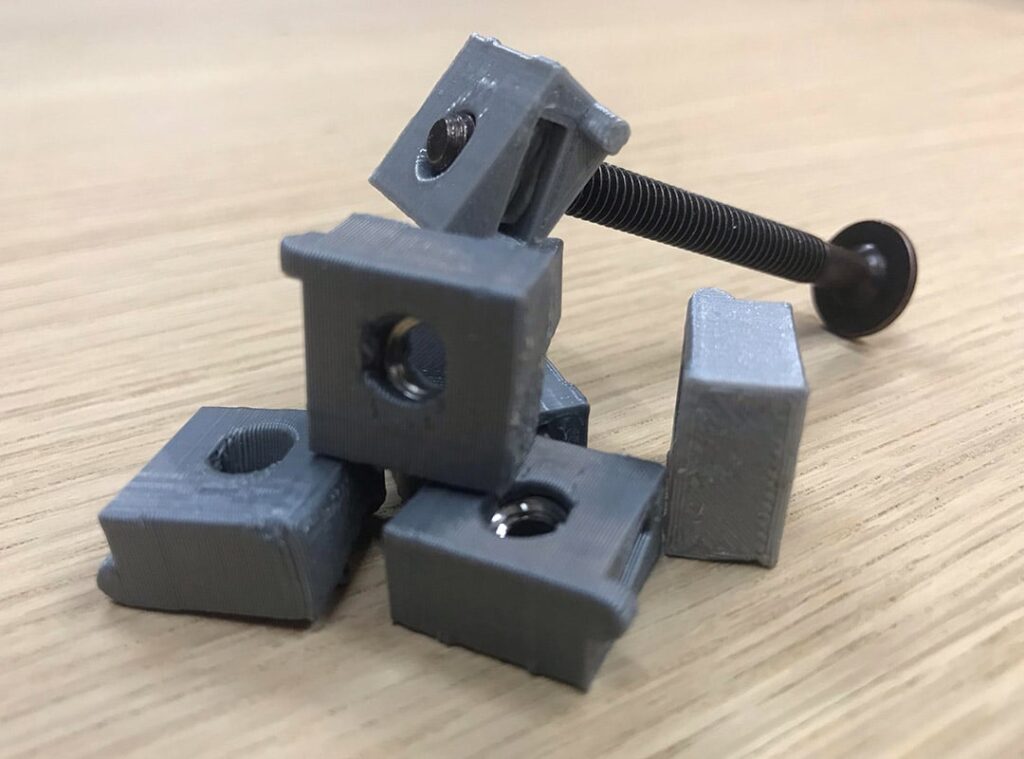

That hammering Jamie can be seen doing in the video? Gone. If it’s hard work to assemble, that’s not good. 4 different leg connectors? No. Let’s make it 1 type across everything. Steel pins to insert at home? Great, that makes transport so much more efficient, and they’re strong too.

It would be much easier to use a plastic component to connect the legs, but we don’t really want to use plastic, so we changed that to be a clever little notch cut to work with a steel bolt, which is reusable again and again.

Of course, all these awesome features have to be cut, tested, refined, cut again, then chatted about for a while, then finalised. And that’s what we’ve been doing here. So now a better joint has made it to the final production line, and believe it or not that really excites us!

Sustainable flatpack doesn’t stop with us designing for usability. Whilst it makes us sad, we have a responsibility to think about what happens at the end (this should be at least 20 years, but hey). So we’ve future-proofed the recycling of our products, every type of material we use can be fully separated back to its original type. This is hugely important for recyclability, and for us saving and re-using those materials to make more beautiful furniture in the future.

I promise to write again soon with tales of what’s been going on in Grain’s workshop- at the moment we are working on some super clever and exciting new products, so watch this space!